Bill Moynihan

Bill Moynihan is a woodworker with prior career in computers and computer software. When he contacted us about testing SketchList D we were happy to have him kick the tires. Recently Bill provided this narrative and image of his experience using SketchList 3D for furniture design.

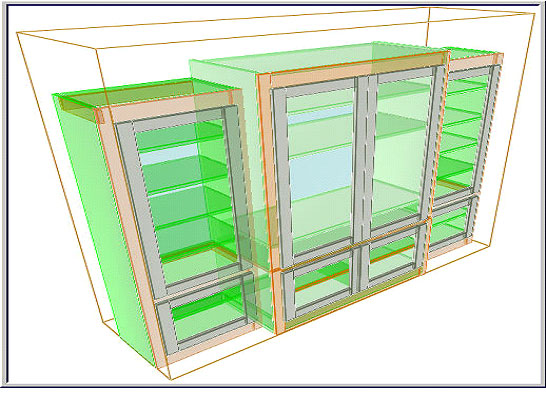

“I was planning to build an entertainment center with one center cabinet and two side curio cabinets. I also wanted the center cabinet to have doors to close over the TV. To make the center cabinet easier to fabricate and move into the house from the workshop, I planned to make it in two pieces that can stack together.

I had some pencil sketches but using a CAD program was expensive and required a long learning curve. Google SketchUp also looked like a long learning curve. I have Cutlist Plus LT Edition, but that is not a design package.

Searching the Web, I found the Sketchlist 3D site. They were looking for woodworkers to test the product prior to product rollout. Such a deal, test a woodworking design product while designing a real world piece of furniture. I have a background in Software Quality Control so it was a good fit with my skills.

I signed up and downloaded the test software. I was very impressed. After an evening “playing” with the software and watching a few video tutorials, I was able to effectively use the program. The User Interface is basically intuitive and easy to use. I could quickly work with boards in 2D or 3D instead of adding many lines using Cartesian coordinates. The package is based on a user defined project space that can contain multiple user defined assemblies that are offset from the project spaces bottom, left, front corner. While working in an assembly, the user inputs locations referencing positions in the assembly and the software takes care of the object position in the project.

Adding boards was simply accomplished by the user defining the board thickness to be orientated when it is added to an Assembly.

I have the ability to clone assemblies to save time in design situations. This saved time with the two curio cabinets.

I can generate parts and purchase lists.

I can generate cutting diagrams and optimize the layout of parts on them and specify the kerf of the blade I will be using

There are both 2D and 3D views of the assemblies and the project. The 3D view also allows the user to rotate an assembly or the project to check perspective and parts placement.

I can input the cost of materials and SketchList 3D will calculate material costs from the material used in the project.

There are many more features too numerous to mention here.

{Editor’s note: Designers use multiple colors to help them see different parts. When the same brown color is used for all boards, details can be more difficult to see.}

As I was testing the software, I also learned a lot about woodworking in areas that I had little previous experience. In my experience, there were some program anomalies (Bugs) uncovered during my testing. The developers have quickly fixed them.

Since I was also testing the software, it is difficult to track the time to develop my project. I do know that it was a lot quicker than a solid modeling CAD package and a lot more fun seeing the results grow on screen.